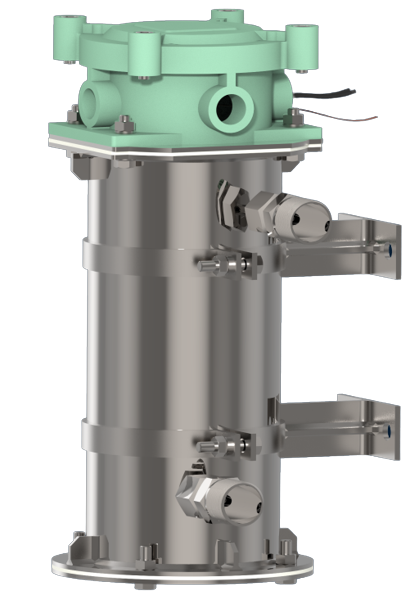

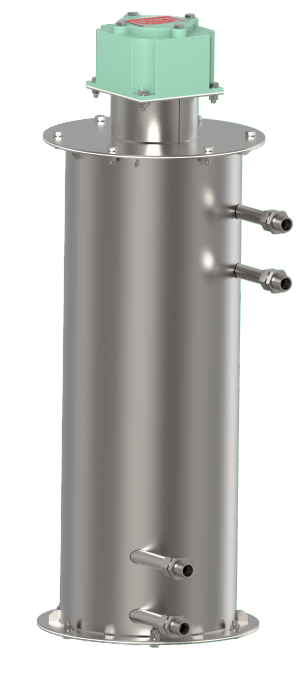

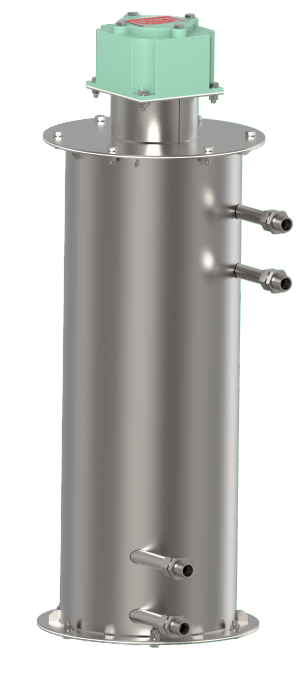

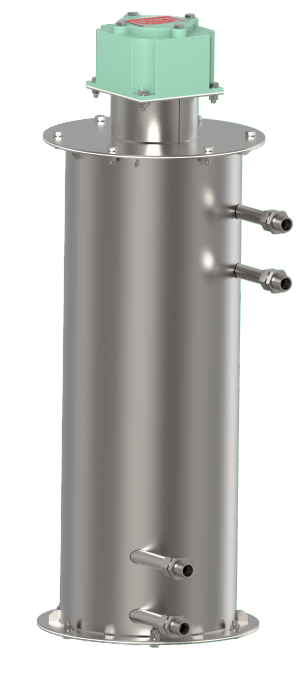

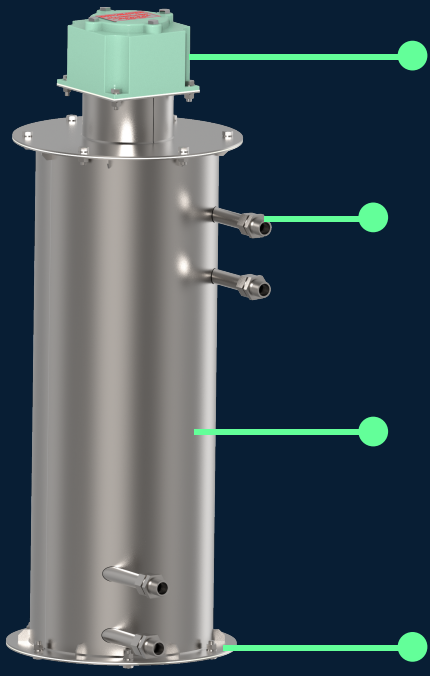

The DRY HEATER® uses electric heating to heat or vaporize the fluids through an isolated flow-path. In this design the fluid never contacts the electrical heating element which brings three key benefits to your application.

Electrical heating elements are notorious for leaching chemicals into the process which contaminates the process fluid rendering it useless. In the DRYHEATER® the process fluid is isolated in a separate tube away from the heating elements making contamination impossible. Therefore the DRYHEATER® is the chosen heater for food and pharma applications.

The isolated flow channels for the process fluids are rated for 150 Bar pressure which makes the DRYHEATER® the preferred choice for heating cryogenics and high pressure gases.

As the process fluid never touches the electrical heating elements, the risk of flame or explosion is radically minimized. DRYHEATER® is therefore the preferred choice for heating Petroleum products and gases.

IEC'S Dry Heaters differs from conventional heaters in a few ways which prove to be highly advantageous.

The heating element does not come into direct contact with the process fluid. This feature eliminates the risk of contamination of the process fluid with compounds from the heating element.

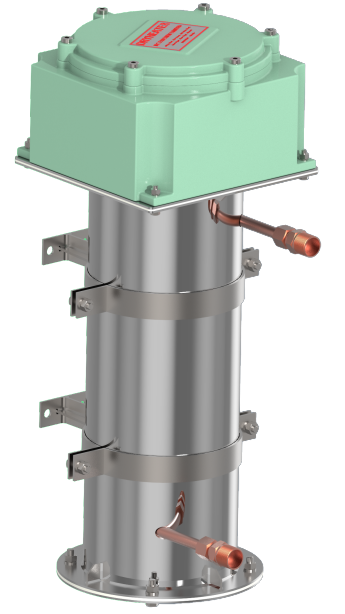

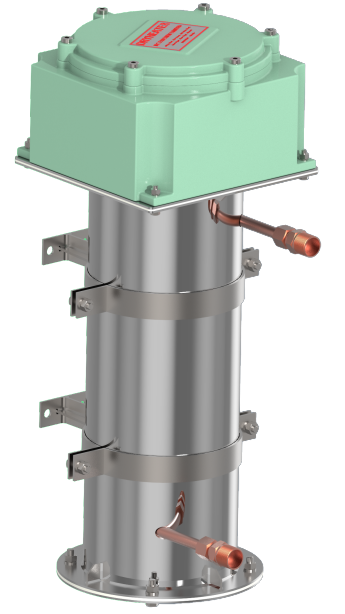

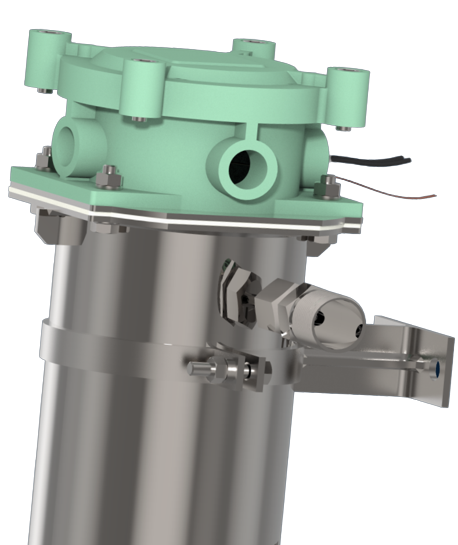

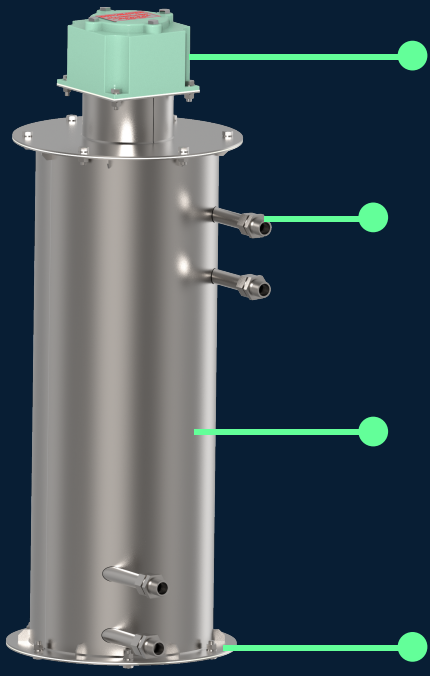

There is no liquid-based heat transfer medium such as a water bath or thermic oil baths. The heat transfer medium is solid aluminium or bronze.

Unlike normal process heaters the fluid medium can travel at a high velocity inside the heater which increases the heat transfer rate

High heat transfer area.

Excellent heat transfer capabilities.

Reliable design Operational safety.

Less susceptible to freeze-up and liquid entrainment.

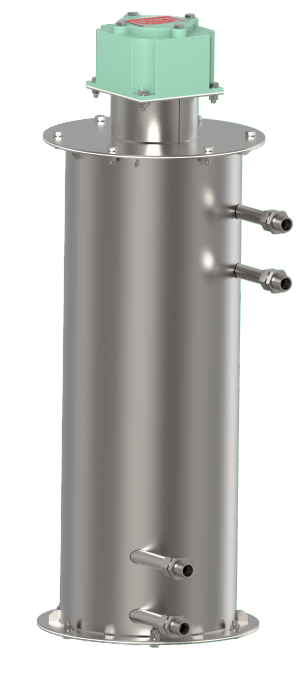

Lower footprint.

Robust construction

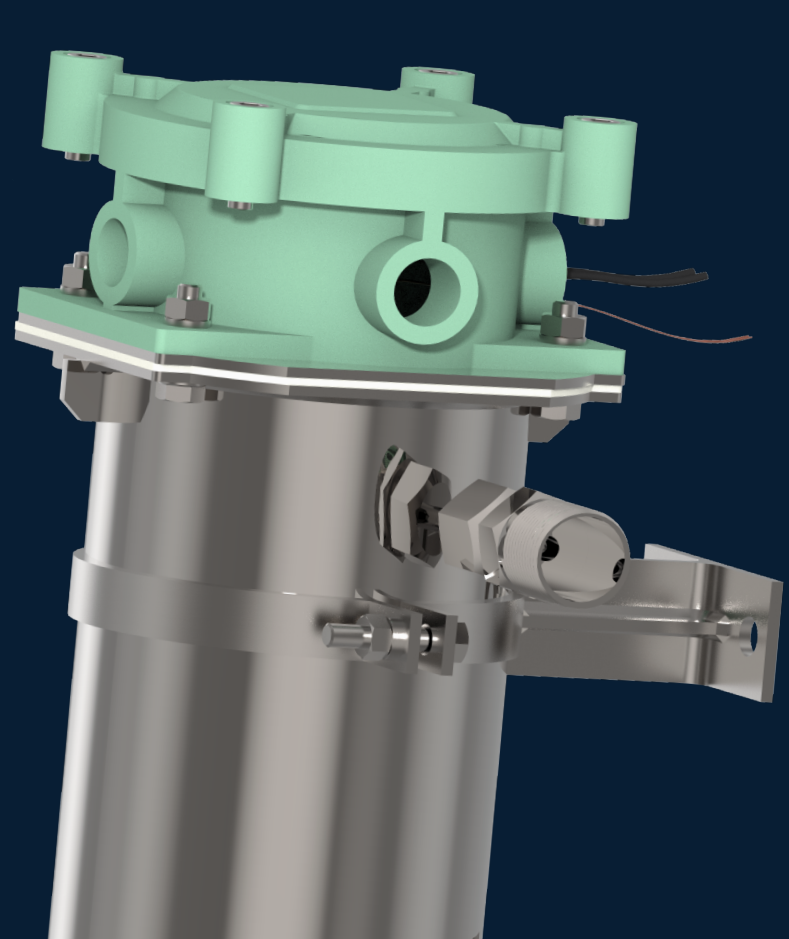

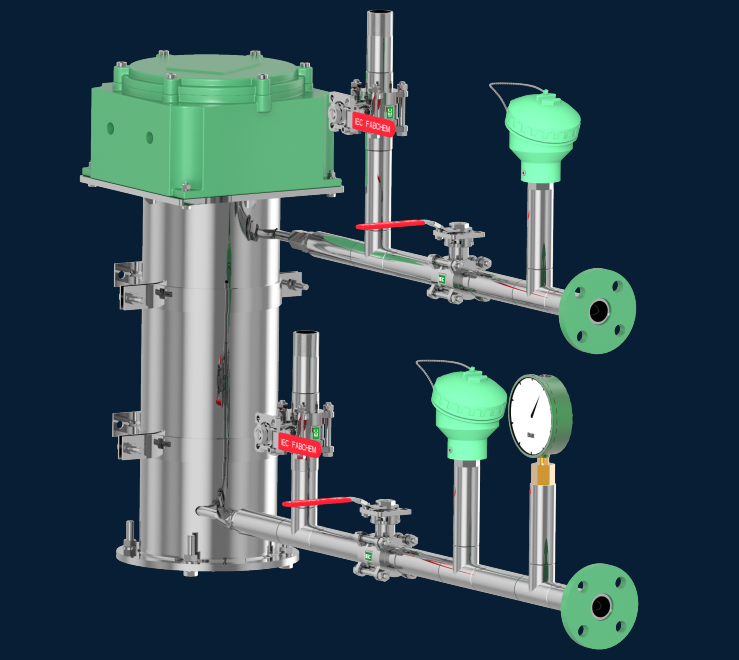

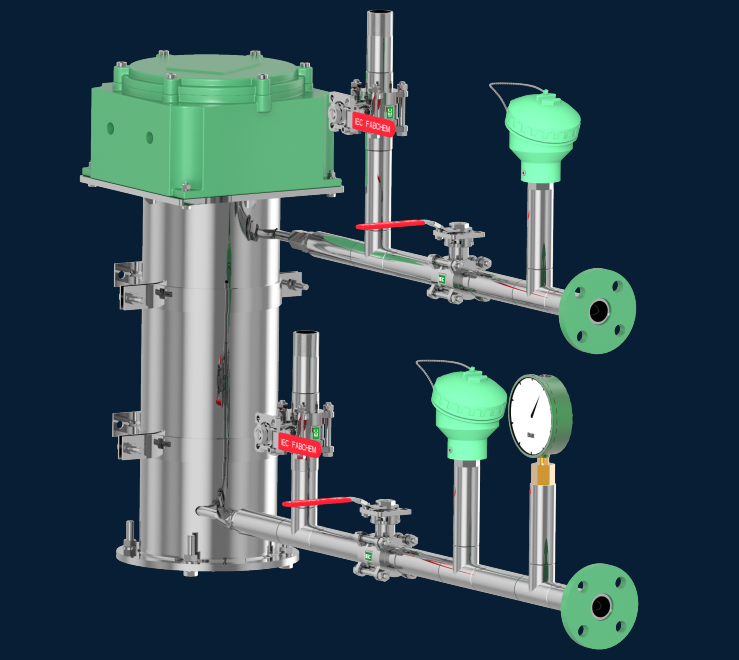

Integrated temperature control system.

Integrated pressure and flow control system.

Fire proof system

Stainless Steel and various MOC flow path tubes according to the specific process application.

Electric heaters can be replaced instantly.

Ability to heat liquids and gases as well.

Ability to safely heat flammable media.

Isolated in flow path tube that never contacts the heating elements.

Suitable for high pressure applications.

High heat transfer rates.

FIRE PROOF EB

QUICK FIT ATTACHMENTS

CORROSION PROOF

COMPACT SIZE